Showroom

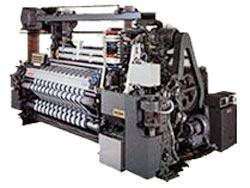

This Weaving Loom Machinery

is highly efficient and is broadly used to weave fabrics made of cotton, silk,

and synthetic fibres. It is in high demand in the competitive market as it uses

less power and is easy to operate.

Rapier Weaving Loom is

commonly used in the textile industry for the production of fabrics for

apparel, upholstery, home textiles, and technical textiles. It provides

dependable and effective weaving processes, enabling producers to satisfy the

needs of different market sectors.

In the textile business,

Electronic Jacquard Rapier Looms are often used, especially for weaving

exquisite textiles like brocades, damasks, and tapestries. They provide the

benefits of effective rapier insertion mixed with the adaptability of

electronic jacquard shedding, enabling the quick and accurate production of

intricate motifs.

Flexible Rapier Looms are a

type of rapier weaving looms that are designed to handle a wide range of

fabrics, including those with varying thicknesses, weights, and fiber types.

They provide more adaptability and flexibility while weaving different types of

textiles.

Jacquard Looms are weaving

machines that use a Jacquard shedding mechanism to create intricate patterns

and designs in woven fabrics. They are well-known in the market for their

capacity to weave elaborate patterns, including intricate designs, pictures,

and even three-dimensional effects.

To create a broad variety of

woven materials, Loom Machine is frequently employed in a variety of sectors,

including textiles, fashion, upholstery, and interior design. Its features may

vary depending on the intricacy, desired fabric type, and manufacturing need.

Automatic Shuttle Change Loom

is a type of weaving loom that is equipped with mechanism that enable the

shuttle to be changed throughout the weaving process remotely. It is frequently

employed in high-volume, high-speed textile production, where productivity and

minimal downtime are essential.

Call Me Free

Call Me Free